First. Unpacking, assembly and start-up of the new machine

After unpacking the new machine, check and accept the accessories, spare parts, tools, technical data and instruction manual according to the packing list. Assemble the sub-packaged parts (such as saw handles, etc.) according to the requirements of the technical data and instructions.

According to the relevant regulations of the gasoline engine, make preparations before starting and start the gasoline engine. Run at idle speed for 3 to 5 minutes after starting, and pay attention to check whether the gasoline engine has abnormal phenomena or noises. If the technical performance is normal, you can increase the throttle, increase the speed, and drive the sawing mechanism through the transmission device to perform sawing operations.

Second, the adjustment of the chain saw

1. Adjustment of gasoline engine

2. Adjustment of transmission device

It mainly includes the adjustment of the clutch spring pretension and the centrifugal force of the clutch block, the adjustment of the side clearance between the clutch block and the passive disc, and the adjustment of the gear tooth gap of the reducer. For the clutch, it is mainly to adjust the tension of the spring to ensure that the tension of each spring is consistent; the second is to adjust the quality of the clutch block. If the weight difference exceeds the specified value (1 g) due to uneven wear, it must be adjusted or replaced; for the reducer The adjustment of the tooth gap is mainly realized by adding and subtracting the adjusting shim.

3. Adjustment of sawn timber structure

It mainly includes the adjustment of the tension of the saw chain and the adjustment or trimming of each cutting angle of the saw chain planer.

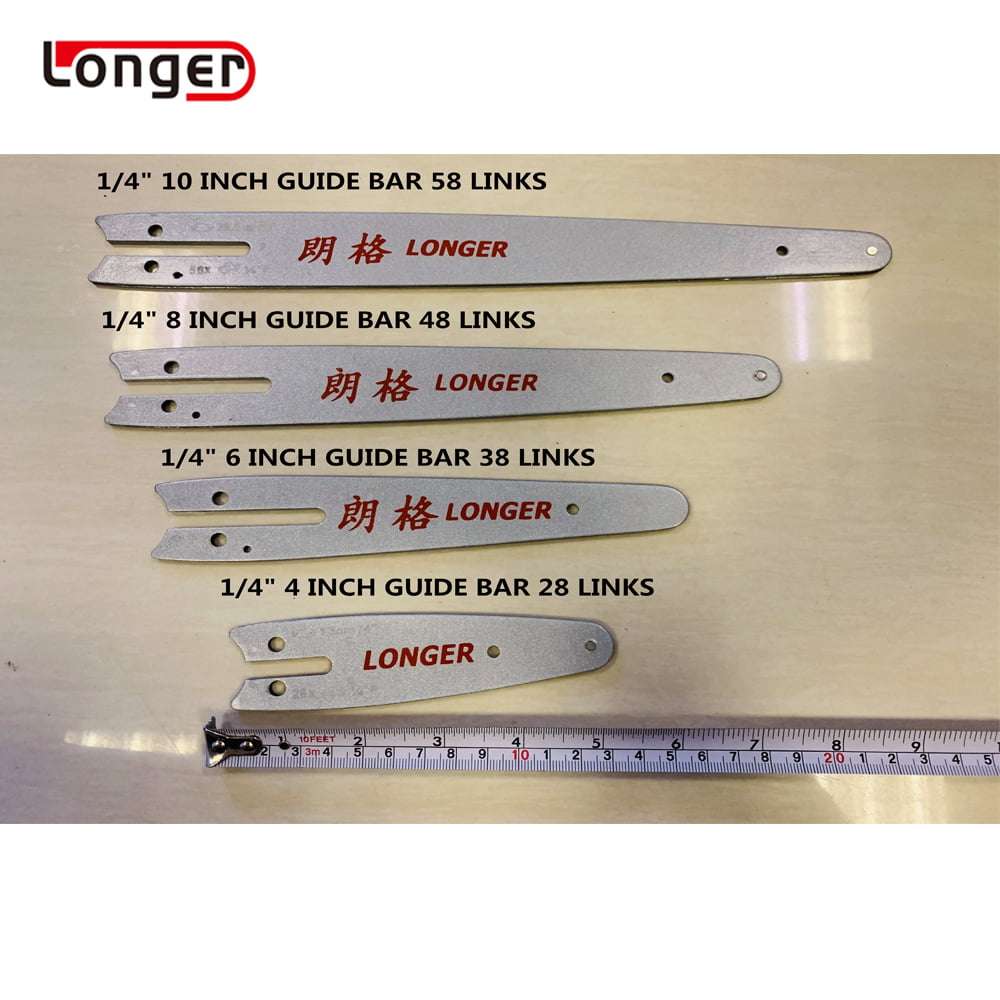

(1) Adjustment of saw chain tension. The adjustment of the tension of the saw chain is achieved by changing the relative position of the saw guide plate and the drive sprocket. The adjustment standard for the tension of the saw chain is: the saw chain can rotate freely on the saw guide plate, and when the saw chain is lightly lifted upwards at the middle of the guide plate, the middle guide teeth leave the chain guide groove of the saw guide plate and keep 0.5-1mm away from the edge of the guide plate. mm is suitable.

(2) Trimming and setting of sawtooth. The cutting edge of the planer tooth should be regularly repaired. Before filing and sawing, adjust the tension of the saw chain to make it suitable. Then fix the saw guide plate, use a round file with a diameter of 5.5-6 mm, and push the file in the direction indicated by the arrow in Figure 4-41a. The left and right planer teeth are filed separately. When pushing the file, it can only be pushed forward, not back and forth. The round file should be close to the horizontal edge and vertical edge of the cutting edge, and should be at the same height as the horizontal edge. Neither the connecting piece nor the limited teeth can be filed off. The angles of each edge must be filed at one time, and must meet the technical requirements specified in Figure 4-41.

The edge angle of the left and right planer teeth should be consistent with the width of the saw edge to prevent the saw chain from running off when sawing wood. The extension lines of the tooth tips of the horizontal blades of the left and right planer teeth should overlap by 1 mm, and the distance between the outer sides of the tooth tops of the left and right planer teeth (that is, the width of the kerf) should be 8.1 to 8.7 mm. If not, use a wrench to clamp the left and right planer teeth, move them lightly to the left and right respectively.

(3) Operation of the chain saw. After the chain saw is started, it can be put into full-load sawing operation after 3 to 5 minutes of idling operation or 20 to 30 hours of running-in with medium and small loads for the new machine.

Third. Correct use of chain saws

1. Before use, you must carefully read the instruction manual of the chain saw to understand the characteristics, technical performance and precautions of the chain saw.

2. Fill the fuel tank and oil tank before use; adjust the tightness of the saw chain, neither too loose nor too tight.

3. The operator should wear work clothes, a helmet, labor protection gloves, dust-proof glasses or a face shield before operation.

4. After the engine starts, the operator holds the rear saw handle with his right hand and the front saw handle with his left hand. The angle between the machine and the ground should not exceed 60°, but the angle should not be too small, otherwise it will be difficult to operate.

5. When cutting, the lower branches should be sawed off first, and then the upper branches should be sawed off. Heavy or large branches should be cut in sections.

6. In order to avoid damaging the branches or the saw chain being clamped, when sawing thick branches, first saw an unloading incision on the lower side of the branch, that is, use the end of the saw chain to saw an arc-shaped incision under the branch, so that the branch can cut off its own weight. down. If there is a pinch saw, add a sharp wedge to the middle of the saw kerf, and then slowly pull out the saw chain.

7. When a new chain saw is used, it must be run-in with medium and small loads for 30 days before it can enter full-load operation.

8. When using high-branch chain saws, pay attention to non-slip feet, and maintain a stable posture when working on site.

9. When operating the chain saw, smoke and fire should be strictly prohibited, so as not to cause a fire.

Fourth, the maintenance of the chain saw

1. Before operation, when adding fuel, the fuel tank port and cover must be cleaned before refueling to prevent mud and sand from entering the fuel tank. The ratio of gasoline to engine oil is 25:1, and the mixed oil is best prepared and used now.

2. Before operation, the lubrication degree of the saw chain should be checked. The saw chain cannot work without lubrication, and the dry saw chain will cause damage to the machine parts.

3. During the operation, it is found that the efficiency of the saw chain is low, and even when the branches are not cut, it means that the saw chain is blunt, and it should be stopped for maintenance and the cutting teeth should be filed. When filing, you can use a three-edged file. When filing the serrated teeth, you can only push forward with force, and do not file back.

4. After operation, wipe the outside of the machine clean, add lubricating oil to the saw chain, and pay attention to sun protection and moisture protection.

5. When not in use, the engine should be fully maintained, the engine oil should be drained, the saw chain and guide plate should be disassembled and cleaned, and stored in a ventilated and dry place for safekeeping.